Less so when you clean it and apply finishes. The leather itself will smell pretty bad for a bit. which will vary in success depending on the patterns you are engraving! So, if you plan doing cutting or engraving with natural veg tan, I'd recommend using something like frisket film, or any other low adhesive contact film to protect your work surface. Cleaning it out is easy enough, but then it gets soot all over your leather. But you are basically vaporising the leather, and that leaves soot behind. I use mine for doing initials mostly, and sometimes cool logos and things. but I'm still learning.Įngraving, is good. But as a general rule: the bigger it is, the more power, the more charring.

I will have a go next I'm in the shop and let you know.

I have not tried much thicker than that since I first got it and worked out most of the kinks. Thin stuff like pigskin or kangaroo, or leather around 1.5mm (3-4oz): no problem. Now lets talk about cutting and engraving.

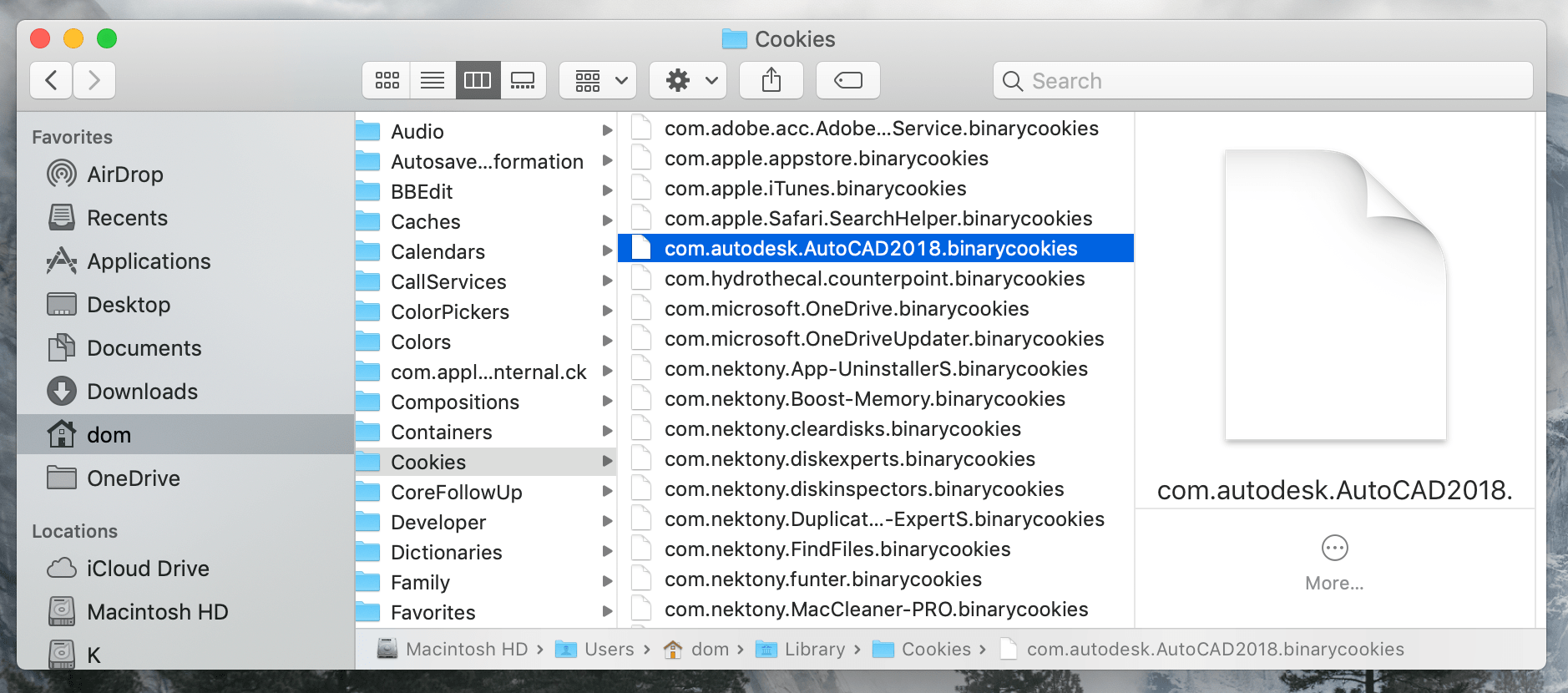

#Draftsight 2018 is junk for free

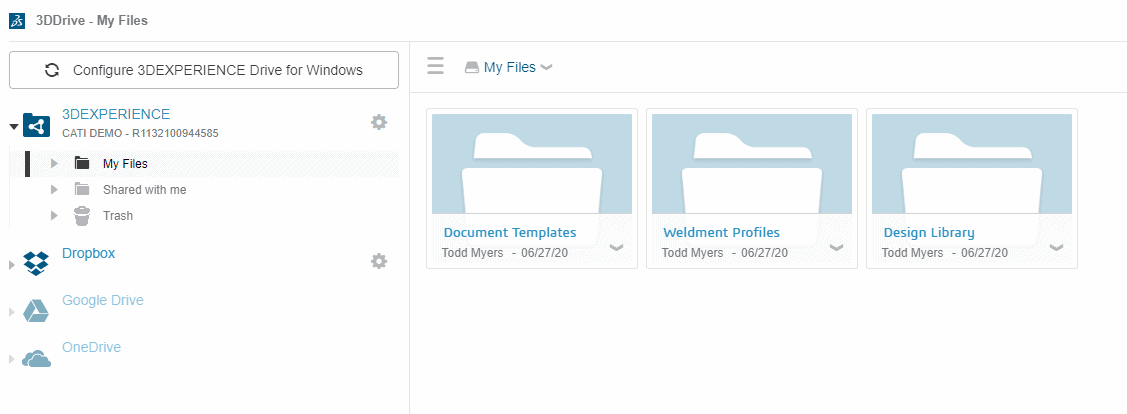

It will also run with any DXF file, so you can download draftsight for free and make all the things you need, and feed them straight to the laser. MASSIVE improvement, and no need to touch Corel draw. k40 whisperer does some cool stuff, like enabling you to run cut, vector engrave, and raster engrave using different colours in your design file. I think they may support mac? Not sure though. I just switched to it, and it seems really great. I removed the lense and turned it upside down, because it wasn't cutting well, now it cuts better.įor software: have a look at K40 whisperer. Not enough to worry about, but cutting a large acrylic template it was off by about 1-2mm The rails appear to be sliiiiightly out of square on my unit. Took me a long time, but once done holds its own. The laser is dangerous when in operation, so always keep the lid closed and wear safety gear if necessary.Īligning the mirrors sucked. It also has a stupid way of fitting it, including a rectangular attachment to a round fan. which leaves everything pretty open and the smoke escapes. Mine died early, and even when it worked it didn't do much. I pour mine into the bucket, operate the machine, and then funnel it back into the container to avoid evaporation loss of my demineralised water. Otherwise you'll get mineral buildup in the laser and tubes. I recommend using a compression clamp to hold the hose in place.Īlso, use only demineralised water. which becomes a serious hazard when the hose pops off the pump and water starts spraying all over the place (i.e "power board")like a fountain. But the hose isn't long, so you don't get much reach, which means it'll usually be right beside the laser. It is dangerous from the perspective that you typically have an open water container next to an electrical outlet and equipment (in my case, the pump is in a bucket on the floor. The pump works fine, but just any old aquarium pump will work fine if you wanted to replace it. It also has a female one on the back of it and operates like a double adapter. I connected the earth wire to a specially designed cable that has an earth wire running to the male end of a lead. In Australia we have 3 prong power sockets. Ok this thread is pretty big and I'm on a train so I'll give you some of my experiences with my K40 laser I bought from ebay.Įarthing, it tells you to connect a wire to a ground probe.

0 kommentar(er)

0 kommentar(er)